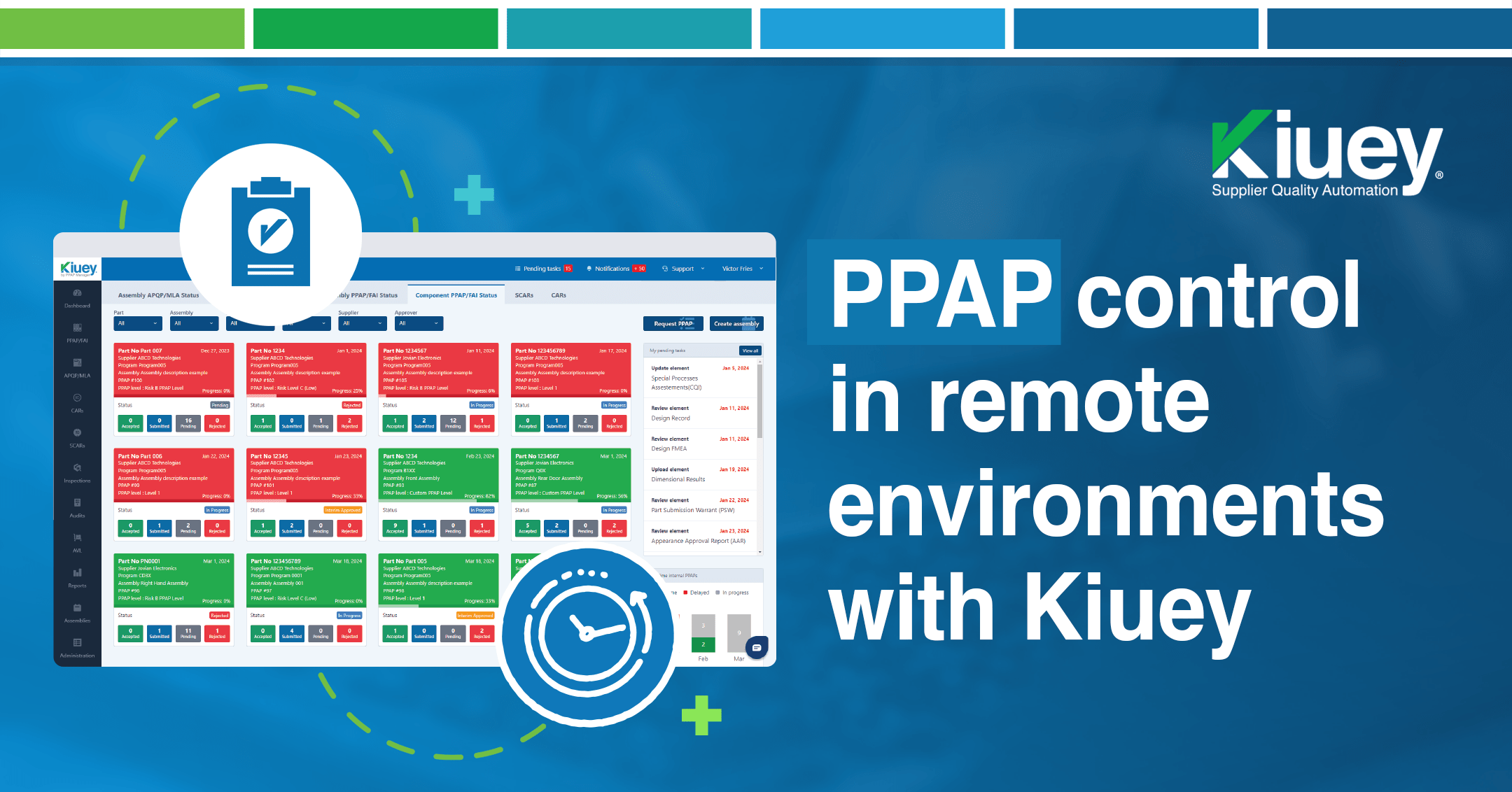

Kiuey’s PPAP Manager: The Key to Efficient Remote PPAP Management

Today, SQEs have to tackle remote PPAP management challenges. Traditional paper-based or manual methods aren’t enough.

Streamlining Quality: How Contract Lifecycle Management Drives Improvement

Ensuring consistent quality throughout the supply chain is a constant pursuit for organizations. Contract lifecycle management (CLM) plays a vital role in this endeavor. By implementing a robust CLM system, companies can establish a framework for collaboration, communication, and continuous improvement with their suppliers, ultimately leading to[…]

IMDS in PPAP and how to manage their complex framework

Within the PPAP framework lies the concept of IMDS, a data exchange format that streamlines information within the automotive supply chain.

A quick guide on how to address Interim PPAP Documentation Issues

The interim PPAP documentation issues can confound even the most adept professionals. Get to know a little bit more about how to solve them.

About SPC: The essentials of Statistical Process Control in PPAP management

In a nutshell, Statistical Process Control is a systematic approach to monitoring and controlling the quality of manufacturing processes.

The guide to what an Appearance Approval Report (AAR) must include

For an SQE, the Appearance Approval Report (AAR) becomes your secret weapon in industries where aesthetics matter as much as functionality.

What you must know about Part Submission Warrant (PSW) for PPAP requirements

A Part Submission Warrant (PSW) is a critical component of PPAPs. A well-constructed PSW can benefit SQEs in several ways.

The Importance of GR&R in PPAP Processes

The key to achieving accuracy & reliability assurance of a Measurement System for PPAP lies in GR&R (Gauge Repeatability & Reproducibility).

Mastering the Art of PFMEA as part of the requirements for PPAP: The Crucial Elements Supplier Quality Engineers Cannot Ignore

Overlooking certain elements in your PFMEA could create a chain reaction of failures, jeopardizing your company’s reputation and bottom line.

The essential PPAP checklist – what to know about each requirement

Any SQE or SQE Manager may know nearly everything about the essential PPAP requirements, but it’s worth remembering and identifying them.

Let's talk to see how PPAP Manager can help your company to save time and money.